Supercritical CO2 power cycles are gaining increasing attention in the engineering world. sCO2 is an ideal working fluid for use in power generating turbines because it offers high efficiency in a compact footprint and can be matched to many different heat sources. sCO2 power turbines could potentially replace steam cycles in a wide variety of power generation applications resulting in higher efficiencies and lower cost of electricity.

Supercritical CO2 is a fluid state of carbon dioxide where it is held above its critical pressure and critical temperature which causes the gas to go beyond liquid or gas into a phase where it acts as both simultaneously. Many fluids can achieve supercritical states and supercritical steam has been used in power generation for decades. Supercritical CO2 has many unique properties that allow it to dissolve materials like a liquid but also flow like a gas. sCO2 is non-toxic and non-flammable and is used as an environmentally-friendly solvent for decaffeinating coffee and dry-cleaning clothes.

The use of sCO2 in power turbines has been an active area of research for a number of years, and now multiple companies are bringing early stage commercial products to market. The attraction to using sCO2 in turbines is based on its favorable thermal stability compared to steam which allows for much higher power outputs in a much smaller package than comparable steam cycles. CO2 reaches its supercritical state at moderate conditions and has excellent fluid density and stability while being less corrosive than steam. The challenges in using sCO2 are tied to identifying the best materials that can handle the elevated temperatures and pressures, manufacturing turbo machinery, valves, seals, and of course, costs.

sCO2 power cycles are potentially applicable to a wide variety of power generation applications. Power generation facilities that currently use steam cycles, could in theory, be upgraded to sCO2 that would enable much greater efficiencies and power outputs. Nuclear power, concentrated solar thermal, fossil fuel boilers, geothermal, and shipboard propulsion systems have all been identified as favorable applications for sCO2 cycles and would replace traditional steam Brayton and Rankine cycles. Researchers believe that sCO2 power cycles could lower the cost of electricity approximately 15% over today’s steam cycle technologies. Lower installed cost for sCO2 systems are due to its smaller footprint and reduced balance of plant requirements.

The single phase nature of sCO2 allows for the design of simple, single phase, single pressure exhaust heat exchangers with low gas-side pressure drop. Due to the superior thermal stability and non-flammability of CO2, direct heat exchange from high temperature sources is possible, permitting higher working fluid temperature (and thus higher cycle efficiency). Because sCO2 is a single-phase working fluid, it does not require the heat input for phase change from water to steam and does not create the associated thermal fatigue or corrosion associated with two-phase flow. Lower operation and maintenance costs for sCO2 are possible because plant personnel are not needed for water quality and treatment functions typically found in steam-based plants.

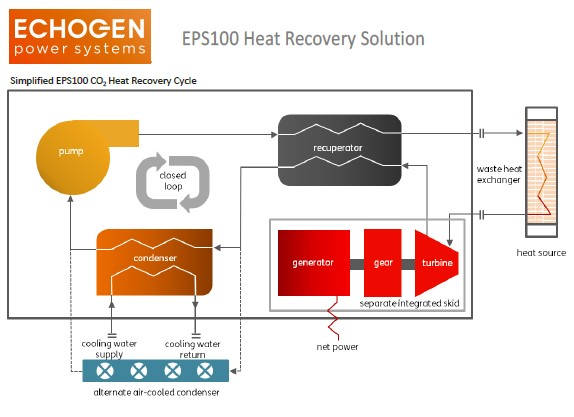

sCO2 can be used in either direct or indirect heating scenarios. Indirect heating would use the CO2 in a closed loop recuperated recompression Brayton or Rankine cycle. Indirect heating could replace steam boilers in coal plants, nuclear power, solar thermal, or heat recovery steam generators used in combined cycles. Indirect heating cycles offer thermal efficiencies greater than 50% and are non-condensing making them ideal for heat sources that offer constant temperatures (such as turbine exhaust).

Echogen is bringing to market their EPS100 8MW heat engine that is targeted for use in combined-cycle applications. Their system is self-contained, closed-loop, and has zero emissions and no water requirements (though water cooling is an option).

Direct heating can use oxy-fuel combustion in a recuperated Brayton cycle to replace coal and natural gas combined cycles and offers the capacity for integrated carbon capture. Direct heating is fuel flexible and is adaptable for coal, syngas or natural gas and is a water producer.

NET Power recently announced they will build their first sCO2 50MW demonstration plant that is direct heated. This power plant is fueled by natural gas and has zero emissions of any kind (no smokestack) and has integrated carbon capture. The plant will output pressurized CO2 that will be sold for use in Enhanced Oil Recovery.

The US Department of Energy is working on integrating sCO2 into nuclear power in order to significantly raise the efficiency and power output. DOE is also working on using sCO2 in solar thermal applications in the Sunshot CSP Program. The Southwest Research Institute (SWRI) and Sandia National Labs have active research programs today in the US and there are other programs in Europe, Asia and in industry.

Ongoing research programs are focused on demonstrating the commercial viability of sCO2 power cycles at increasingly larger power outputs. Rotordynamics continue to be analyzed and optimized. Heat exchanger research seeks to improve heat transfer correlations for varying geometries and improve heat exchanger durability through testing of materials, fabrication, channel geometry, fouling, corrosion and maintenance. Long-term corrosion and materials testing across all components also continue to be active areas of research.